DEUTZ is continuously searching for new tools to make the use of its engines ever more effective and lasting. In this great effort to optimize the customers’ investment and to maximize the performance of each purchased unit, the most recent technologies are essential. The launch of S-DEUTZ Telematics adds another important element for the establishment of a better connection between DEUTZ assistance service and its customers.

Better control reduces downtime

This new service aims to improve both the customer’s and the assistance’s control of the state of the engines. In this way, it’s possible to achieve an effective collaboration on both sides to avoid undesirable machine downtimes which are a source of potential losses, sometimes even serious ones.

An active service everywhere

DEUTZ hardware and software infrastructure can monitor the state of the engine in real time, and in numerous countries in Europe and around the world. In this way, the customer will instantly receive all the information necessary to prevent any arising faults. Soon the service will also be available in Italian.

AI for DEUTZ engines

The telematic system for detecting the state of the engine leverages an artificial intelligence system capable of programming the timing of each maintenance phase in a more precise way. The real-time detection of all types of error codes makes it possible to develop a highly accurate diagnostic process. A whole series of parameters will then be analyzed, which allows to have a correct overview of the state of the engine at all times.

S-DEUTZ Telematics characteristics

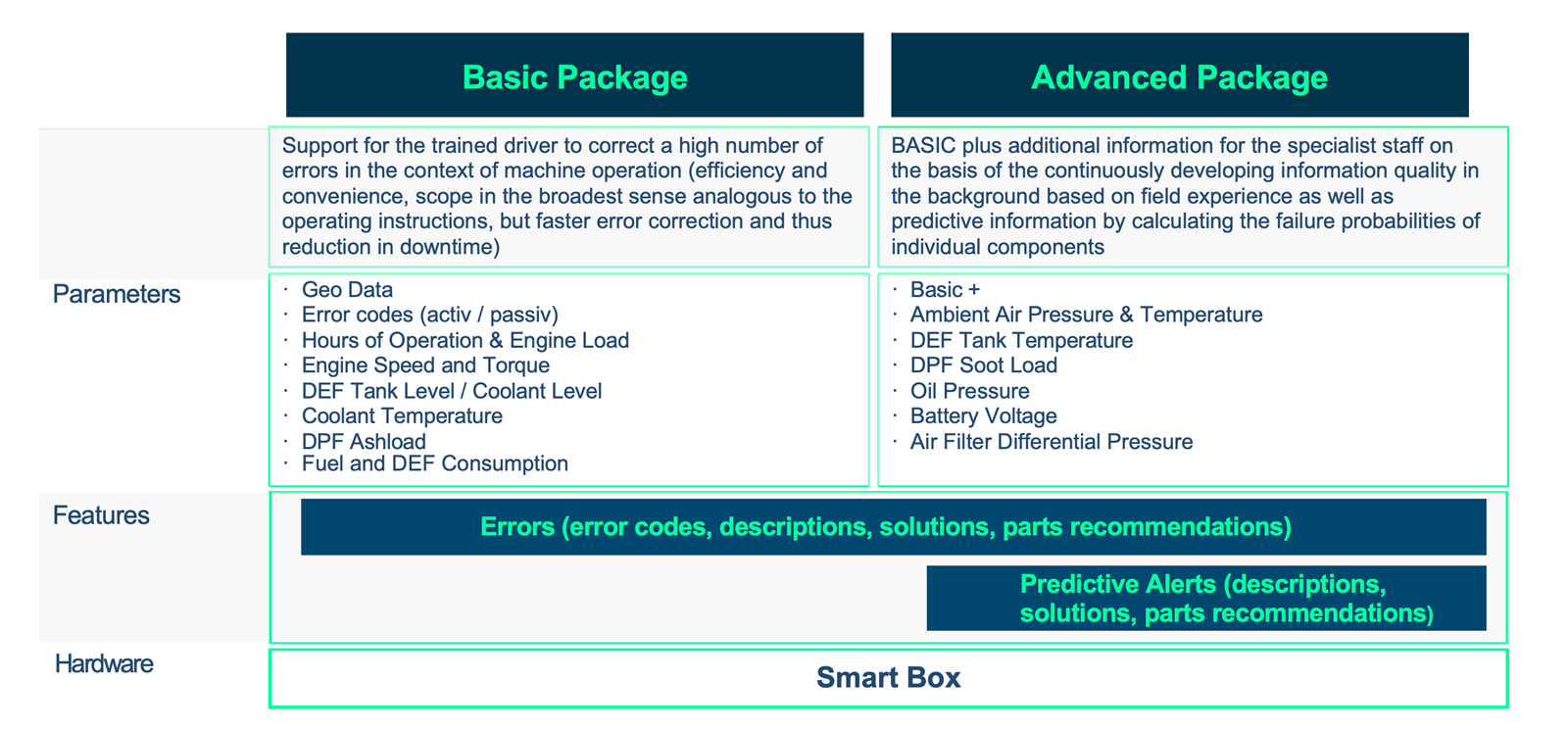

The Telematics packages are two and they vary in terms of available services of the telematic assistance network. It’s possible to choose between the “Basic” package or the “Advanced” one.

Both packages include the smartbox and a series of common services.

- Geolocation information

- Error codes (active and passive)

- Operating hours and engine load

- Motor speed and torque

- DEF tank level / Coolant level

- Coolant temperature

- DPF ash load

- Fuel consumption and DEF

- Errors (error codes, descriptions, solutions, spare parts recommendations)

- Predictive alerts (descriptions, solutions, spare parts recommendations)

This type of service allows the user, with an appropriate training, to correct some errors that may occur during normal machine operation.

Additional services are included in the “Advanced” package.

- Outside air pressure and temperature

- DEF tank temperature

- DPF soot loading

- Oil pressure

- Battery voltage

- Air filter pressure differential

This additional information allows the system to store information that will progressively feed the predictive system. The result will be a more precise and rational scheduling of ordinary and extraordinary maintenance, thanks to a more exact calculation of the probability of failure of the individual components.

The three pillars of the monitoring system

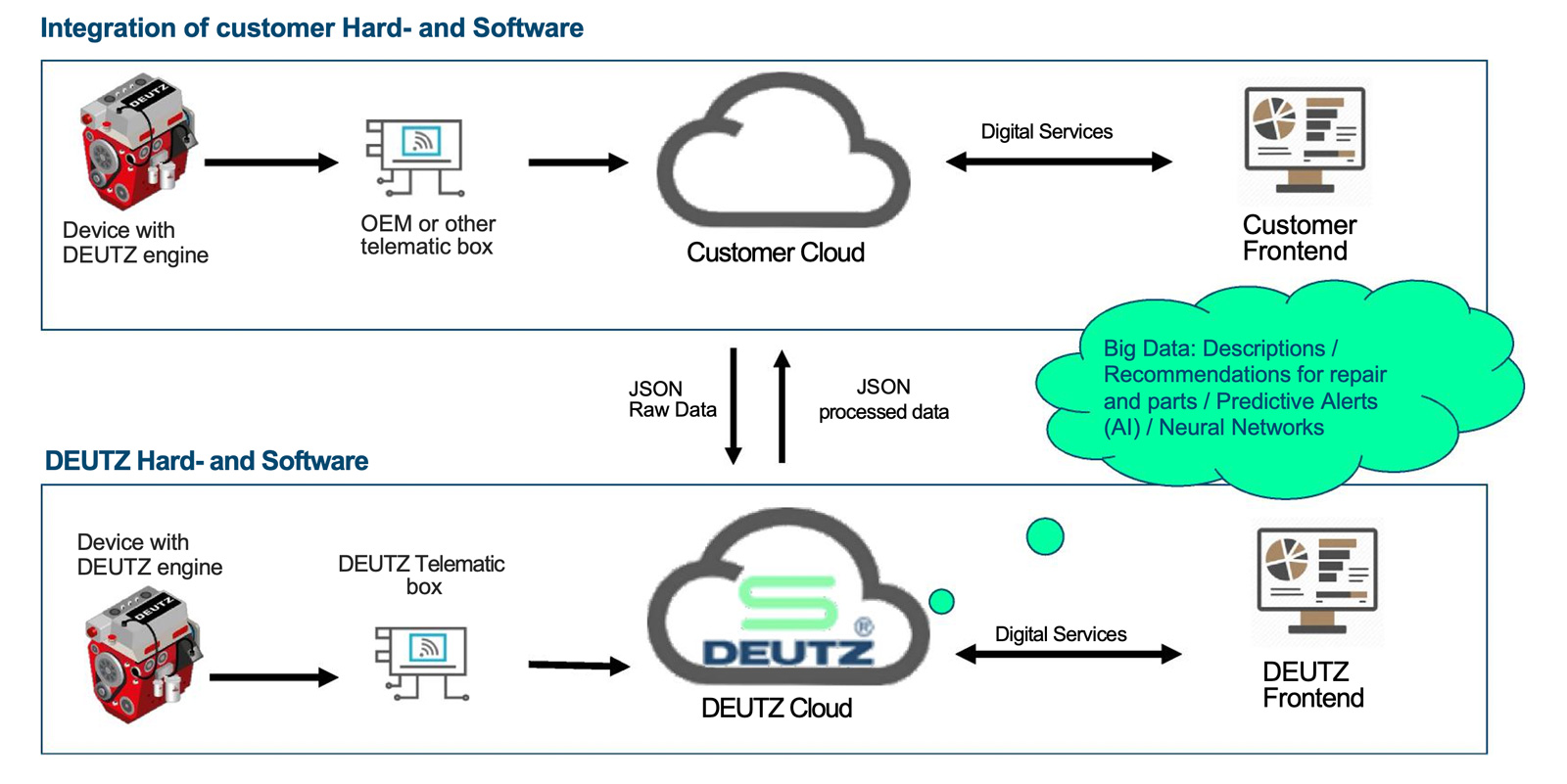

The S-DEUTZ Telematics system is based on three infrastructural elements.

The first is a smartbox that connects to the engine and communicates outside via an integrated sim card included in the price. The second is the antenna system compatible with the 2G/3G/4G network to send the collected data. The third consists of the cloud infrastructure where all the information coming from the engines that are part of the S-DEUTZ Telematics network are stored and processed. This is how the AI system will be able to process the received data.

The telematics control panel

The result of this process is displayed on the telematic control panel which makes all data available to the customer. In this way, suggestions become available for a more precise scheduled maintenance, oriented towards the individual problems of the engine. The so-called predictive recommendations elaborated by artificial intelligence are also available.

The information is divided into four main screens

The Telematics control panel is divided into four main sections.

The first deals with monitoring the engine with regard to performance and the level of harmful emissions. The second catalogs the working calendar of the engine, including the worked hours. The third section highlights all the error reports and provides all the predictive information to minimize any arising failures. The fourth contains a whole series of additional services that can be activated at any time by the customer.

How to obtain and use S-DEUTZ Telematics

Telematics service activation process involves purchasing and receiving the smartbox and connecting it to the engine. Via the telematic control panel it’s possible to activate the telemetry unit and associate it with the engine by entering the relevant serial number. The functions that can be activated will depend on the type of the chosen package. The price of S-DEUTZ Telematics varies according to the number of engines connected to the service.

Customer needs and expected results

Such a service satisfies specific and important customer needs with results that have a significant impact on the running costs of the units. Knowing how to prevent problems and breakdowns and identifying the necessary spare parts has always been essential for the DEUTZ engines customer. Furthermore, with better scheduling of ordinary maintenance activities, general management costs for the machines fleet will be reduced. With perfectly efficient engines, significant fuel savings are achieved even for older engines. The result is a considerable general saving which has a very substantial impact on the current costs of maintaining the working units.

Comparison between S-DEUTZ Telematics and third-party services

Until now, some customers relied on third-party services that processed the provided data to obtain better optimization of the repairs and maintenance phase. Thanks to S-DEUTZ Telematics, all information is received from whoever built the engine itself, with an undeniable advantage in terms of know-how in fault management. The result will be the best possible assistance that progresses day after day, thanks to the use of artificial intelligence.

Choose the telematic control of your DEUTZ engines

Relying on S-DEUTZ Telematics means having a top-level machine fleet management level, with the minimization of engine downtimes and with substantial savings in each phase of use. Because today, an optimized maintenance process involves also the use of the network and artificial intelligence.